ELMO Design

ELMO is designed with the purpose of being a test bed UAV to evaluate the performance of a range of electric engine configurations. As such, ELMO is a conventional and stable flight platform with the modularity capability integrated throughout the airframe that allows ELMO to fulfil its research aim.

Wing

-

Designed to produce a certain amount of lift at cruise speed and take-off.

-

Combination of ribs and spars to guarantee stability.

-

Flaps to achieve high lift performance.

-

Ailerons added for roll control.

-

Servos for control surfaces.

Tail

-

Evaluated to have the best shape and components.

-

Vertical plane under fuselage in order to provide additional rudder area and protect the propeller.

-

Lower stabiliser outside of wake of horizontal plane, perfect for spin scenario.

-

Control surfaces managed by inline servos.

-

The rudder is optimised to counter any possible propeller failures.

-

3D printed parts to hold structure together.

Fuselage

-

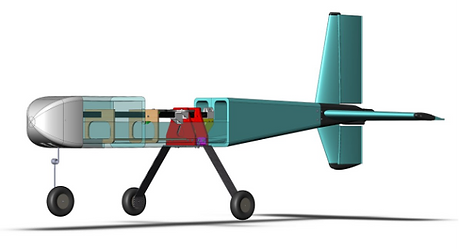

Carbon fibre landing gear designed to withstand excessive loading.

-

Steerable nose gear.

-

Carbon fibre sandwich bulkheads to transfer loads to main spar.

-

Nose designed in tandem with landing gear and easy to remove.

-

Central structure held together by spars and attachments

-

Brackets in order to secure flight if there is a bonding failure.

-

Physically tested up to 170N.

Avionics

Flight Controller

-

Includes autopilot mode.

-

Easy to set up and open source software.

Receiver

-

Small and light.

-

Up to 16 channels.

Power Units

-

710W motor in fuselage and 340W in wings.

-

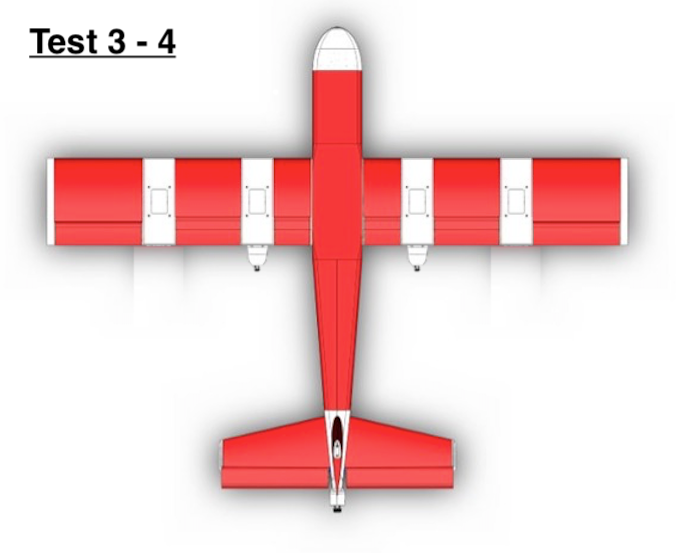

Tractor or pusher tests on the wing.

-

Upper and lower surface of wing tests.

-

Designed to be positioned in any wing propulsion layout.

ELMO's Research Configurations